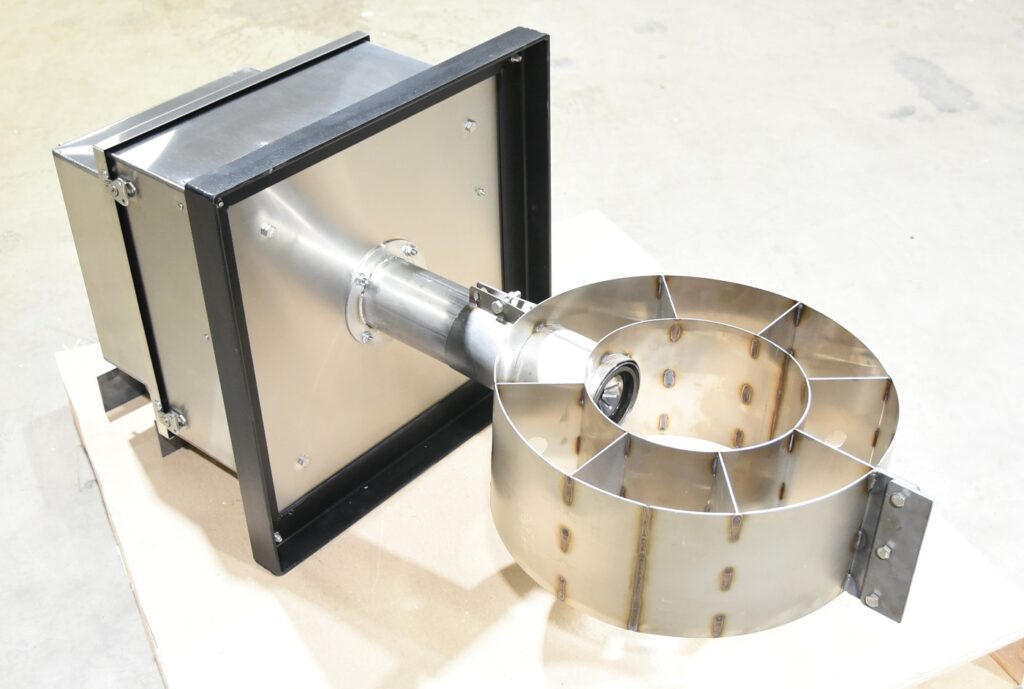

Model C Belt Heater

Eliminate down time on small, slow moving, inclined belts where materials slide back or slip due to frost or ice. No more clean-up or labor expenses required.

Specifications

- Applicable on belts up to 36 inches wide, up to 350 FPM

- Propane/Natural Gas or Diesel

- Heat output 50,000 to 200,000 BTUs adjustable

- Operational to -40 degrees

- Sealed, lifetime stainless steel construction is not affected by the elements

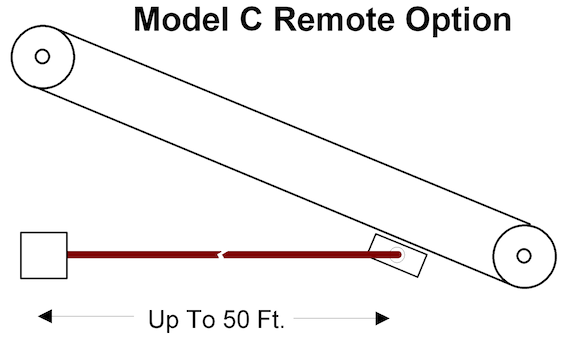

- Air Filtration (not affected by dust, for extremely dusty conditions, a remote air filtering option is available that allows fresh air to be ducted from almost any distance)

- 110/120v 220/240v Single Phase, 50/60 Hz

Patented

Options

- Standard Heater

- Propane / Natural Gas, Diesel Fired Heater 50,000 - 400,000 BTUs adjustable

- Portable/Mobile Heater

- Portable Diesel Fired Heater 50,000 - 400,000 BTUs

adjustable

Stainless Steel Construction

Suspended Below the Belt

Welded to Belt Structure

Contact Us

before the cold weather returns!