HTR™ Heated Wear Liners

Heated wear liners eliminate material freezing and sticking in chutes, bins and hoppers at any temperature. This method of keeping your materials flowing will eliminate significant downtime, labor expenses and lost production. Construction costs, inefficient heating systems and confined spaces with their cleanup issues can be eliminated greatly reducing costs.

The installation of heated liners can save tens, even hundreds of thousands of dollars compared to the cost of enclosing, heating and maintaining large areas involving thousands of square feet, where a few hundred square feet of surface is all that needs to be heated. By eliminating enclosures, you eliminate confined spaces requiring hand labor to maintain compared to using a machine.

Heated wear liners are a direct replacement or overlay for your existing liners. Bolt-in or weld-in to meet your requirements.

Any type of wear surface in any thickness is available in Mild Steel to AR400/500. Chromium Carbide, Stainless Steel, Ceramic TIVAR, UHMW, Rubber...... You name it.

The basic liner can be overlaid with additional wear plates welded in place in high wear areas as the need arises.

Standard Controller

Activates the system when the temperature falls below the set point on the thermostat. Applicable for freezing issues.

Optional Controller

Maintains constant temperatures as required in some applications dealing with sticking of wet materials.

Specification

- Available in any voltage from 120 - 600

- 100-200 watts per sq. ft to prevent freezing

- 200-500 watts per square ft to prevent sticking of wet clays or other similar materials

- Operational at - 40 Degrees

Patent Pending

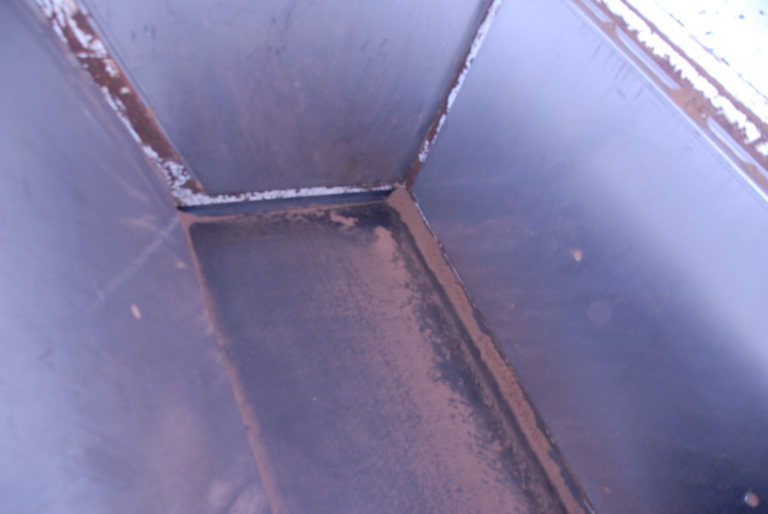

Weld in AR 400 Liner Installation

Stainless Steel

Thermostatically Controlled,

Set It and Forget It !!

Standard Controller

Optional Controller

Contact Us

before the cold weather returns!