Applied Traction Technology (ATT)

Drive roll slippage or spin out on drive rolls cause down time, lost production and can damage belts and lagging on drive rolls. ATT is an automated abrasive blasting system. Designed to stop drive roll slippage on belts conveying biomass or other combustible materials and belts operating underground where a high temperature heater cannot be used due to fire hazard.

650lb. Capacity

Adjustable Height

Angles, and Swivels

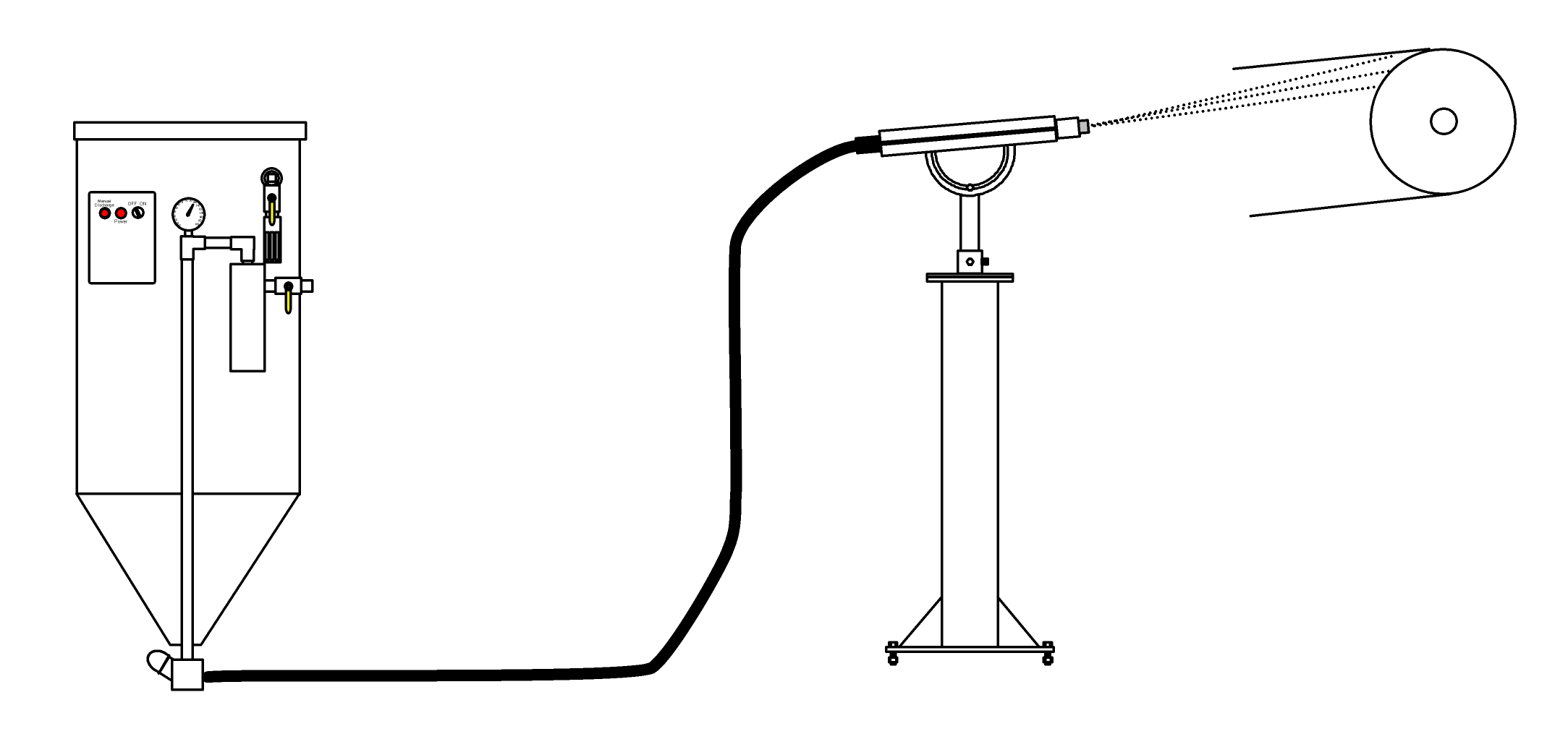

The Applied Traction Technology System

The system consists of a pressurized container that holds the blast media and a mounted blast nozzle that directs the media into the pinch point where the belt wraps around the roll. There are two speed sensors that monitor the belt and drive roll speed. If the belt slows below the speed of the drive roll, the system is activated and blows abrasive onto the drive roll, instantly increasing traction. When the speeds are synchronized the system is deactivated.

Patent Pending

Contact Us

before the cold weather returns!