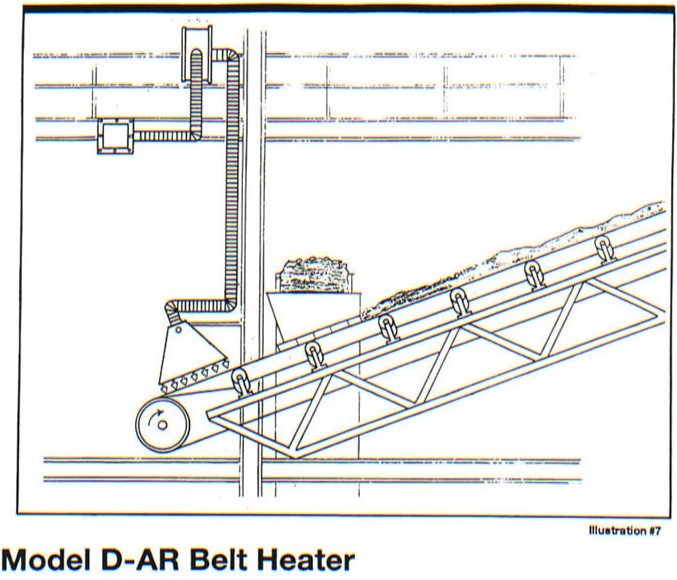

Model D-AR Belt Heater

This illustration shows a Model D heater with an AR combustion chamber being used to de-ice a belt to eliminate material slide-back. This type of installation is desirable when the tail section of the conveyor belt is inaccessible or space is limited.

Model D-AR Belt Heater – Safety

The safe operation of Thermo-Tech Model D-AR Belt Heater systems is the most important concern. Thermo-Tech units are designed to stop operating any time that the belt even begins to slow down. UL and CSA approved burners and controls used in commercial / residential heating systems assures a safe operating system. Model D-AR’s open design does not collect spillage from the underside of the belt and the heaters do not retain heat after they stop. MSHA has test and endorsed the use of the Model D-AR Belt Heater systems.

Model D-AR Belt Heater – Durability

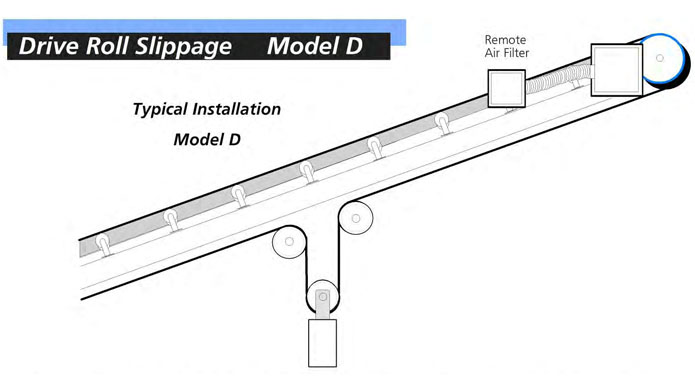

Model D-AR Belt Heater is a patented design of Thermo-Tech’s, constructed from grade 304 and grade 309 stainless steel. They are weather resistant and sealed dust tight. Neither rain, snow, ice, or moisture will affect operation.They are designed to operate in a variety of dusty, dirty conditions by utilizing a remote air filtering system that can be located 40 feet or more from the installed unit.

Model D-AR Belt Heater – Dependability

The Mode D-AR Belt Heater systems typically will operate throughout the winter without any maintenance. They use of stainless steel in the construction and burners and controls used in time tested home / commercial furnaces, as well as components used in get aircraft engines make for a lasting and dependable system.

Economical Operation – Model D-AR Belt Heaters

Thermo-Tech’s Model D-AR Belt Heaters are known for economical operation. Downtime is totally eliminated with the Model D-AR Belt Heaters due to frost and ice build up or accumulation when they are properly specified, installed and operated. This claim is backed by our 100% satisfaction guarantee. A typical 56 inch belt running at 500 ft per minute that is experiencing material slide back can be treated with this system using approximately 2.5 gallons of diesel fuel or 3.75 gallons of propane per hour. Larger belts require more, smaller belts require less. Initial acquisition cost and minimal fuel consumption is typically a fraction of lost revenues due to downtime or labor and consumable costs incurred using alternative methods of de-icing.