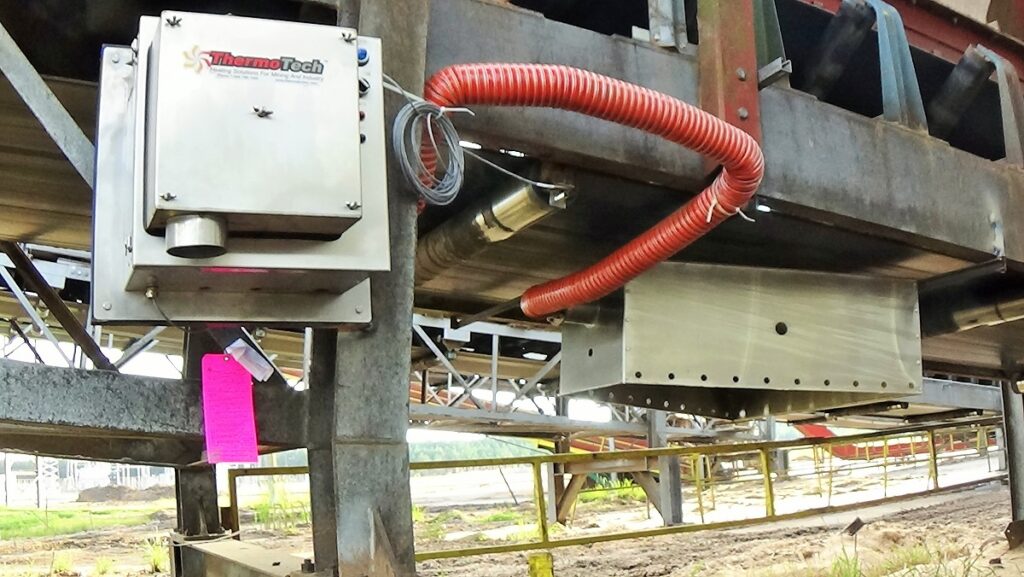

Model D Belt Heater

- Save time on start-up by removing frost and ice from belt surfaces

- Eliminate down time caused by ice forming on the belt during operations from water or moisture in the material and from blowing snow

- Eliminate down time caused by material slide back or slipping on inclined belts due to frost, ice, or water

- Eliminate the need for cleated or chevron belts and stop the mess they create

There are only two reliable methods of keeping conveyor

belts operating under severe conditions. Enclose the

entire belt structure and maintain a temperature that

will keep ice from forming or heat it with a direct flame.

A direct flame is safe as long as it stops when the belt

stops and is not used on belts that convey highly

combustible materials such as sawdust. Thermo-Tech’s

patented and proven system is permitted by MSHA

(United States Mine Safety & Health Administration) for

use on above ground belts.

Specifications

- Applicable to virtually any belt running at any speed

- Propane/Natural Gas or Diesel

- Heat Output 50,000 to 400,000 BTUs Adjustable

- Operational to -40 degrees

- Sealed, Lifetime Stainless Steel Construction

- Air Filtration (not affected by dust, for extremely dusty conditions a remote air filtering option is available that allows fresh air to be ducted from almost any distance)

- 110/120v 220/240v Single Phase, 50/60 Hz

Patented

Options

- Standard Heater

- Propane / Natural Gas, Diesel Fired Heater 50,000 - 400,000 BTUs adjustable

- Portable/Mobile Heater

- Portable Diesel Fired Heater 50,000 - 400,000 BTUs adjustable

Sealed, Stainless Steel, Weathertight Construction

Not Affected by The Elements

Open Design Does Not Accumulate Spillage

Can Withstand Carry Back Falling From the Belt

Watch Video - Ice to Steam Instantly

Contact Us

before the cold weather returns!